Some experimentation was required in order to introduce lead-free metal halide powder into a scintillation screen. The development of an extraordinarily efficient, resilient, and flexible scintillation film by a KAUST team resulted in substantial gains in medical, industrial, and security X-ray imaging once the team figured out the best approach.

Scintillation materials emit visible light, or “scintillate,” as a result of absorbing invisible X-ray high-energy photons, which are otherwise undetectable. In order to generate digital pictures that disclose the relative passage and obstruction of X-rays when they contact any solid object, such as a region of the body, an industrial component, or an object being screened for security concerns, they are employed in conjunction with a computer.

X-ray scintillation is now a commonplace technique, but researchers are constantly looking for methods to make it more sensitive, efficient, and easily adaptable to new environments.

Yang Zhou, a postdoc in Omar Mohammed’s group, explains that “currently utilised materials suffer from a number of limitations, including difficult and expensive production techniques, radioluminescence afterglow, and nontunable scintillation.”

These materials, known as lead halide perovskites, have aroused substantial interest as well as showing tremendous potential. Perovskites, also known as novel perovskites, are a class of materials that have the same crystal structure as the naturally occurring perovskite mineral calcium titanium oxide, but they contain a wide range of different elements that substitute for all or some of the elements found in naturally occurring perovskites. Lead halide perovskites are compounds that contain both lead and one or more elements of the halogen group, such as fluorine, chlorine, bromine, and iodine. Lead halide perovskites are composed of lead and one or more elements of the halogen group.

Due to technical issues, such as low stability when exposed to light and air, absorption of part of the scintillated light, and the poisonous nature of lead, lead halide perovskites are not widely used in commercial applications, despite their excellent X-ray scintillation capabilities.

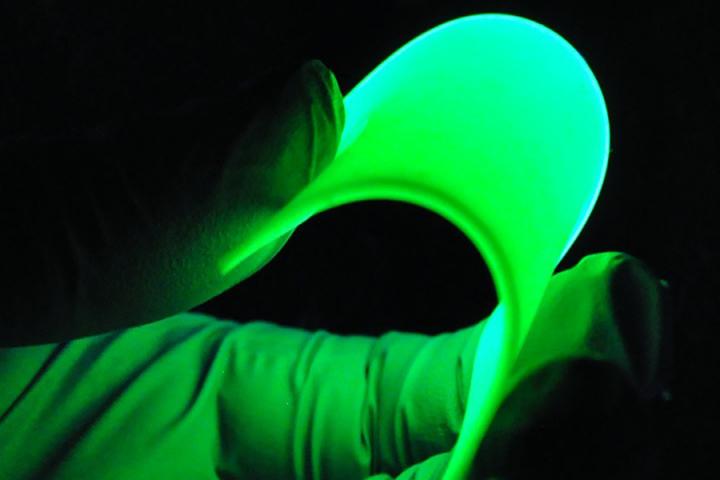

A research team at KAUST has found a solution to these challenges by inventing lead-free metal halides that are composed of the elements cesium, copper, and iodide in the ratio Cs3Cu2I5, with crystals of that material mixed into thin and flexible films made of the plastic polydimethylsiloxane.

According to the researchers, it was difficult to obtain equal distribution of the copper halide particles in the film, but they ultimately succeeded by dispersing the powder in a solvent before adding polydimethylsiloxane.

Omar Mohammed, the group’s leader, states that their flexible scintillation screens can detect X-rays at extremely low doses, which is around 113 times lower than a normal standard dosage for X-ray medical imaging.

Zhou points out that the X-ray spatial resolution described in this work is the greatest ever attained for powder-based screens, which is a significant advancement.

As Mohammed points out, “the physical flexibility of our films is also quite significant.” He says that extremely effective flexible scintillation screens are urgently required for the use of X-rays to better examine difficult forms, and that these screens are currently unavailable.

The team has already begun planning for the commercialization of their advance. Aside from that, they intend to develop their manufacturing procedures and investigate the possibility of screens with comparable material compositions.